Product Design and Engineering Services

Engineering

Our designers combine Industrial Design and Mechanical Engineering to create manufacturing-optimized designs. Efficient workflow with engineering teams and relationships with global suppliers provide seamless continuity in DFM production and component sourcing.

There are a variety of different tools and processes we use to deliver this within the engineering stage. Every project has its own goals and requirements – our product design and engineering services help provide value by recommending which tools and processes are an appropriate fit to meet the needs of your project.

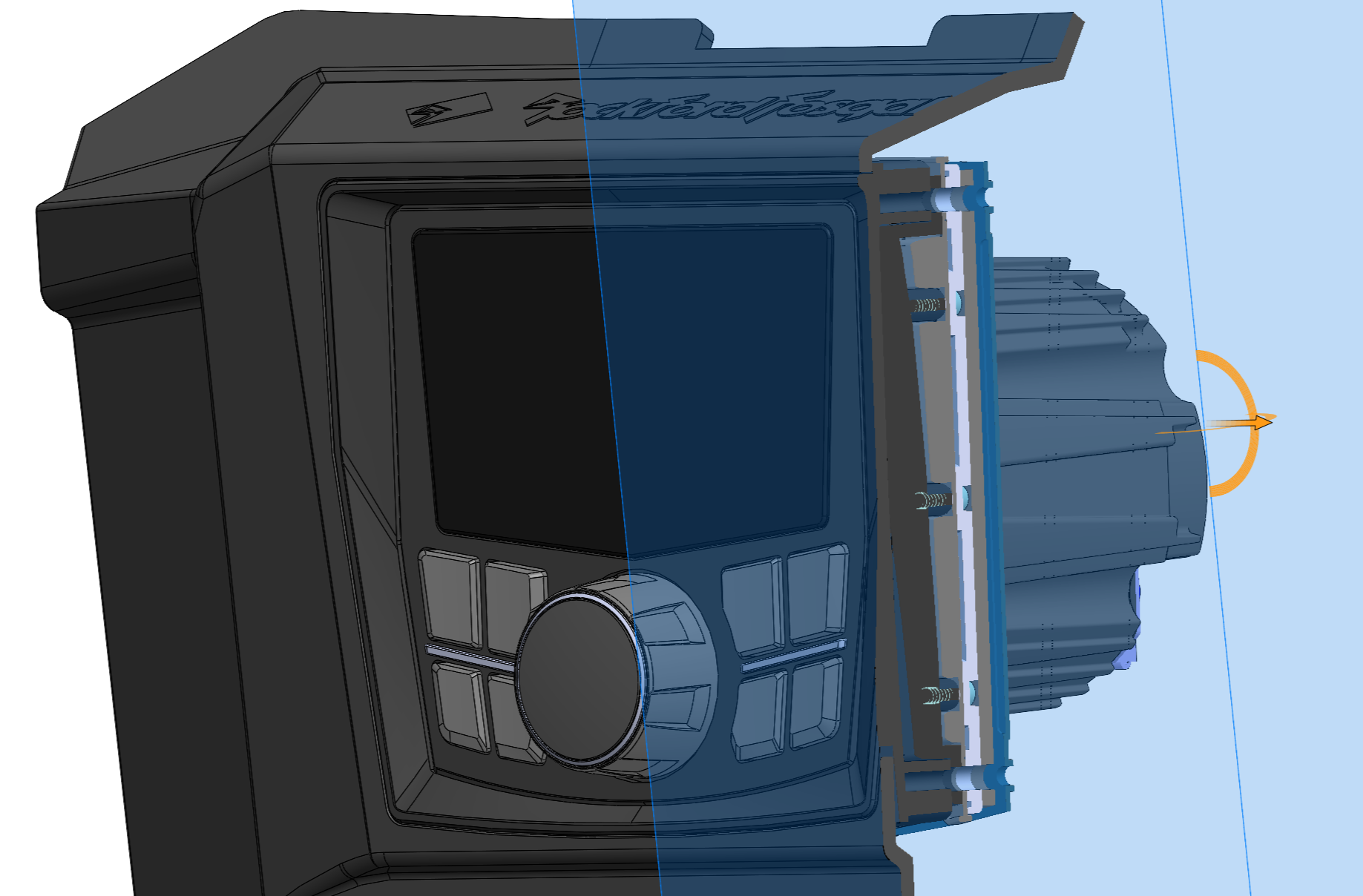

IMPLIED ENGINEERING

The bridge between Industrial Design and Mechanical Engineering CAD development - our designers combine knowledge and implementation of both disciplines to create manufacturing-optimized designs. Efficient workflow with engineering teams and relationships with global suppliers provide continuity in Design for Manufacturing (DFM) and component sourcing.

This implied engineering process offers high cost/time savings, more quality, and a more risk-reduced CAD development workflow. We often use implied engineering results for rapid prototyping models to evaluate product performance and validate the product's design.

The handoff exchange with Mechanical teams is also improved with increased seamless transition. Early on in the design concept phase, we push for continuous improvement of functionality, developing products while we work closely with mechanical teams so that files contain all required details for a smooth handoff.

MECHANICAL ENGINEERING

During the strategy phase, engineers from our mechanical and electrical engineering services teams collaborate to discover opportunities and potential risks during the strategy/discovery phase. These teams carry this collaborative process throughout the development and prototyping.

Our product design and engineering services teams have a keen eye for process, functionality, materials, and manufacturing cost. Combined knowledge from our internal team and design engineering partners help take the existing design and explore efficient processes to be used in manufacturing.

Our mechanical teams bring diverse expertise in various specialties, such as specifications, mechanism development detail engineering, CAD development, DFM analysis, processes DFM, iterative testing, and prototyping. Product development success through engineering services is drastically improved with a strong Product Requirements Document (PRD). Design engineers use engineering requirements from this document as a benchmark for executing the mechanical design. We believe a thorough specification that is closely monitored enhances cycle time and mitigates rework costs during the development phases.

ELECTRICAL ENGINEERING

During the prototype and strategy phase, our mechanical and electrical teams collaborate to discover opportunities and potential risks during the strategy and discovery phase. These teams carry this collaborative design process on throughout the product development cycle, including prototyping.

Our electrical teams bring diverse expertise in various industry specialties, such as control systems for driving motors, actuators, and pumps. Including PCB development, wireless integration, and network connectivity, the engineering team is demonstrating proficiency with RF, Wi-Fi, and Bluetooth technologies to support IoT development.

FAQ’s

-

This question is asked often, and it is really difficult to pinpoint an answer because there are so many variables, from product complexity, testing, user/focus group feedback, certifications, etc. In a perfect world, we recommend our clients allocate up to 8-15 weeks, depending on the complexity and the speed at which client feedback.

2-3 weeks for research/strategy,

3-4 weeks for concept development,

3-5 weeks for mechanical development/implementation,

3-4 weeks for prototyping.

In most cases, this doesn’t mean you are ready for tooling!

We will gladly share a case study of our process and work - walk through a timeline from start to finish to give you a more realistic timeline for your project.

-

In many cases, especially larger product manufacturers an in-house creative team exists. One of our strengths is the ability to adapt and challenge the internal status quo without compromising the creative value you need. We provide cost-effective design support to address the pain points your team is facing.

-

This question comes up frequently, and giving an exact estimate can be challenging due to the presence of several variables. Nevertheless, in many cases, we segment project estimates into distinct phases to ensure transparency and clarity in assessing the required effort.

-

With so much hype recently about AI, it's important to remember AI is just a tool. It can be an excellent tool for specific tasks but not so great for others. We will utilize AI in our process in a supporting role. We contend that AI lacks certain aspects of humanity, particularly empathy, which we consider essential for a user-centered approach to problem-solving and design.

-

Yes. We understand the hurdles and complexities that come with launching a new startup or building a brand — it's no small feat. Recognizing the various challenges, we, as partners, are prepared to contribute our design services as a form of capital tailored to the specific needs of the venture.

-

This varies. Our standard payment terms are net 15 days. We offer flexibility to our long-standing clients and established relationships, allowing for a net payment period of 30 days or more.

-

At the beginning of any project, many preconceived ideas won't materialize or reach fruition. Problem-solving in new product development process is rarely linear. Our objective with any client project is to offer transparency throughout the process, including risks and opportunities. We have a clear goal of providing you with a solution that meets the business objectives while also delivering products your customers will love.